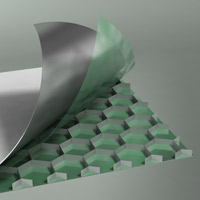

Cleanroom Aluminum Panels

with a Honeycomb Core

Webb Core Cleanroom Wall and Ceiling Panels are designed, manufactured and intended to provide high structural strength with minimal weight. Our cleanroom aluminum panels have an aluminum honeycomb core expanded into a hexagonal structure sandwiched by aluminum skins and bonded with our custom adhesive.

Cleanroom Panels are specifically designed for wall and ceiling cleanfab application, but are used for solutions in other industries. The standard aluminum skin is typically constructed from a 0.032 (0.025, 0.040, 0.063 available) aluminum sheet with an acrylic or epoxy paint finish.

We also offer custom cleanroom panels upon request.

Cleanroom Honeycomb Panel Applications

- Cleanroom Wall Panel Systems & Ceiling Panels

- Structural Applications

- Modular Cleanroom Wall Panel Systems

- Display Systems

- Exhibit Panels

- Veneers and Metal Finishes

- Decorative Partitions

- Fine Art Conservation

- Signage

Cleanroom Panel Finishes

- Designer White

- Conductive White

- Duracoat Polar White Epoxy

- Polar White Acrylic

- Shell White

- Conductive Dissipative

- Static Dissipative

- Custom

Thermostatic Acrylic Enamel

- Dry film thickness: One coat 0.75 -0.85 mil pretreated aluminum

- Hi Gloss: 60 degree 80% minimum

- Pencil Hardness: Eagle Turquoise F-H

- T-Bend: 2T = No Pinch Off .060" - 0.080" heavier gage/harder may go to 4T-NPO

- Adhesion: 1/16" Dry Crosshatch = No Tape Off

- Rev Impact: 1-1/2" times metal thickness = No pinch off

- Acid Resistance: AST5M D968, 30 liters falling sand

- Taber Abrasion: Model 503, Teledyne Taber, SS-10 wheels 450 Cycles to substrate, 54 mg loss @ 450 cycles or .12 mg per cycle.

- Detergent Resistance: 3%, 100 hours @ 100 degrees F - Pass

Webb Core Cleanroom Panels Feature

- Up to a Sub-Class 1 Environment

- Variety of Wall Panel Systems

- Designed to meet all requirements for new and existing facilities

- Ability to integrate with existing modular cleanroom wall panel systems

- Chemical Resistance

- Anti-static Conductivity

- Lightweight Aluminum

- High Strength

- Non-Outgassing

Panel Dimensions and Weight

- Weight: 1.1 lbs./sq. ft.

- Length: up to 174 inches

- Width: up to 48 inches

- Thickness: 0.25 inches - 3 inches Sheet Aluminum

- Chemical Resistance

Performance Tests

- Climbing Drum Peel: 12 in. lb/3 in. Mil-STD-401

- Surface Resisability: 107-9 ohms/sq. ASTM D257

- Climbing Drum Peel: 12 in. lb/3 in. Mil-STD-401

- Flatwise Tensile: 300 PSI Mil-STD-401

- Outgassing:< 0.15 ppm/mg

Epoxy Coating Specifications

- Surface Resistivity: 10 to power of 7 - 10 to power 9 ohms/sq.

- Adhesion (ASTM D3359): 5B

- Film Hardness (ASTM D3363): 2-3H

- Tabor Abrasion: 6.0 mg maximum (ASTM D4060 CS10, 100 Cycles)

- Impact: 12 in-lbs. minimum (ASTM D2794 2 lb., ½" Ball)

- Flexibility: >3T

- Outgassing: .06 ppm/mg maximum